3-PHASE ELECTRIC MOTOR

3-phase electric motor is an electric machine that generates force in the form of torque by converting electrical energy into mechanical energy. The torque exists on the motor’s shaft. 3-phase electric motor gets its power supply from alternating current(ac) sources. This type of electric motor is also known as Induction motor. It is commonly in use in industries, and can be used to achieve conveyance of materials from one position to remote position. Also it is used for crushing , hammering, blowing hot or cold air, pumping etc. Because of their high torque characteristics, they tend to use up enormous instantaneous electrical energy on starting.

The capacity of the electric motor is measured in horse power(HP) or Kilowatts(KW). The higher the capacity, the more dangerous its starting effect is on the overall electrical system where it operates. This is due to it’s inherent characteristic of drawing up high electric current on starting.

However, technology has given rise to an appropriate starting system for this kind of machines. This starting system is Star-Delta Starter. This is a safe starting system for 3-phase induction motors. It allows the effective starting of 3-phase machines without drawing up large amount of electric current.

Operation Of 3-Phase Electric Motor

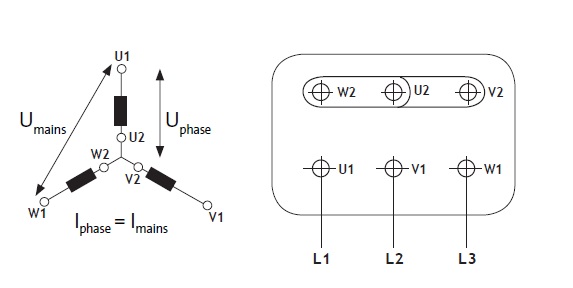

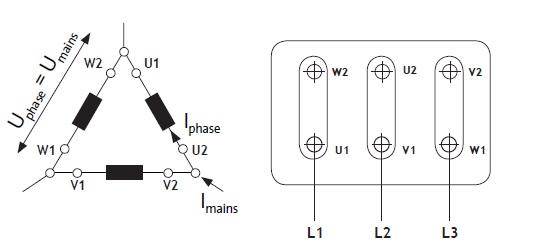

This kind of electric motor is also called 3-phase induction motor. Typically, they operate on two types of connections viz:

- Star Connection When the motor connection is on star, it draws up low and reasonable electric current from the system source. But, this has a low torque or force on the motor shaft and therefore can not perform heavy work load. The advantage is that this connection allows the system circuit to maintain some sort of stability. Moreover, other existing appliances on the same circuit can operate safely at the same time. This kind of connection is quite safe. It is also known as direct-on-line connection on star.

2. Delta connection This gives the motor a high toque on it’s shaft, thus enabling it to perform a much harder job. In order words, this connection makes the motor to overcome the inertia of it’s full load whose value is normally in kilowatts or horse power. If the power supply is direct on this connection, the machine draws up about 300% of the full load current on starting. This causes a disturbance of voltage on the supply lines due to large starting current surges.This situation is not safe for the system circuit that supplies power to the electric motor. Moreover, this situation is more dangerous and unsafe when the motor is of higher capacity.

For this reason, the Institute of Electrical Engineers came up with a recommendation for safety. This states that any 3-phase electric motor of more than 7.5 hp should not operate on Direct-on-line through delta connection. Therefore, direct-on-line installation is better done by using star connection as the starting method.

As a result of the above reasons, the connection of 3-phase electric machines of high capacity more than 7.5 hp, should be through the star-delta starting system.

How Does Star-Delta Starter Function?

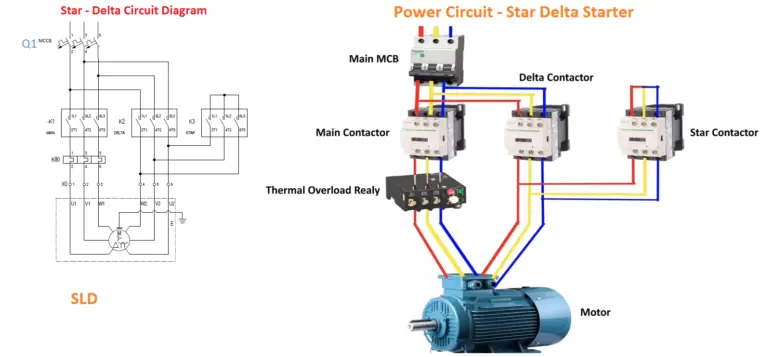

With technological advancement, there are safer methods of starting 3-phase induction machines. One of which is called the star delta starting system. It is now the most common method of starting high capacity 3-phase induction motors. This method, allows the motor to start and run through a star connection. Recall that when the connection is on a star connection, the motor draws minimal current on starting without sufficient torque for hard work. Then as the motor runs on star connection and attains about 80% of it’s full load speed, an electronic timer will automatically change the configuration over after a set amount of time. At this point, the starter automatically changes the motor to delta connection. Also recall that this is the connection that enables the machine to perform it’s full load work.

This is a kind of starting method that reduces the starting current by initially putting the motor on star connection. Then after a preset time, the starter switches the motor on delta connection automatically.

Components Of Star-Delta Starter

A typical star-delta starter comprises of the following components:

- Main Contactor

- Star Contactor

- Delta Contactor

- Electronic Timer

- Overload Relay

- Start Push Button

- Stop Push Button

- Flexible insulated copper wires

All these components are inter connected by means of flexible wires and fixed in a box. The electronic timer is the component that changes the connection from Star to Delta after a predetermined time. Another important component is the overload relay. This one protects the motor winding from overload current, and unbalance voltage supply. If a 3-phase electric motor runs on an unbalance voltage supply, its winding is in the danger of breaking down. Hence the reason for an overload relay.

The start push button does the function of switching on the power supply to the induction motor. Whereas the stop push button disconnects the machine from the power supply.

Therefore star delta starter is most suitable in factories and manufacturing industries where the required starting current must be at a minimum value.

As a professional making use of star delta starters, it is worthwhile to chill out after the day’s activities with Fine Wines. This is a sure way to wind down the day.